Maximizing ROI: The Strategic Value of Robotics in Manufacturing

When considering automation, the key question is Return On Investment (ROI): Will this pay off—and how soon?

In today’s competitive manufacturing landscape, efficiency isn’t just a goal—it’s the standard. The push to produce more, faster and with fewer resources is reshaping operations across every sector. That’s where industrial and collaborative robotics shine.

Robotics is no longer a futuristic concept. It’s a strategic investment that drives efficiency and long-term profitability. It provides practical, accessible tools for companies to scale.

When considering automation, the key question is Return On Investment (ROI): Will this pay off—and how soon?

The answer depends on several key factors. Let’s walk through the biggest contributors to the ROI of automation with robots and what that means for your business.

1. Labor Savings That Scale

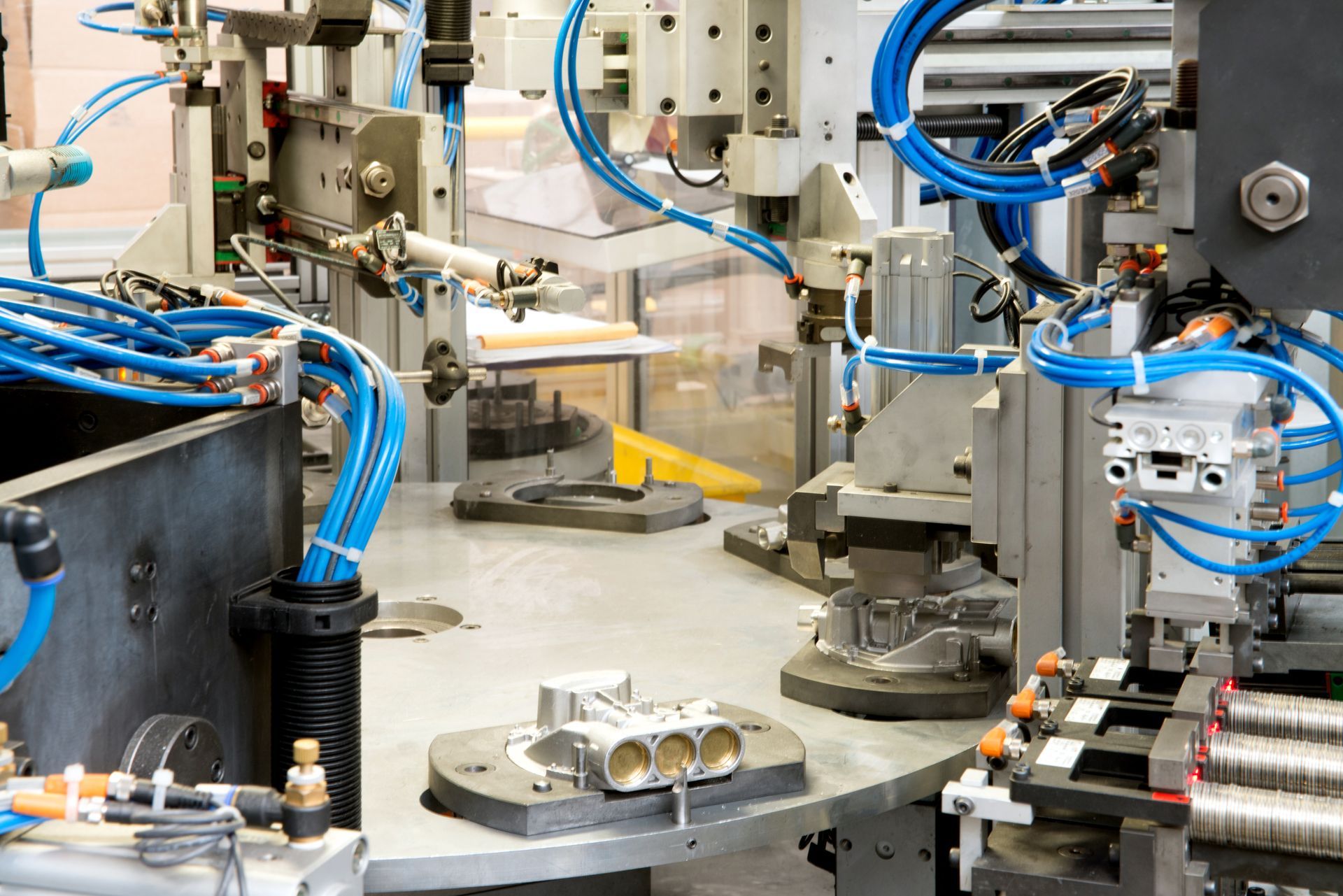

Labor costs are often one of the most significant—and unpredictable—expenses in manufacturing. Robots operate 24/7 without fatigue. They work reliably and consistently across multiple shifts, allowing companies to maintain output even when staffing is tight .

They can also help stabilize your workforce by taking on repetitive, physically demanding or hard-to-fill roles. Robots also excel at time-consuming tasks like welding, assembling and packaging products. Human team members can be reassigned to more strategic or specialized roles that drive additional value for the organization.

For many operations, a reduction in overtime, turnover and temporary labor is enough to see a return on their automation investment within one to two years.

2. Greater Productivity with Existing Resources

Beyond reducing labor costs, robots enhance throughput by helping you get more out of the equipment and floor space you already have.

They minimize downtime, speed up cycle times and streamline workflows. In some cases, facilities can increase output by 20–30% without expanding their physical footprint by simply integrating automation into the right manufacturing processes.

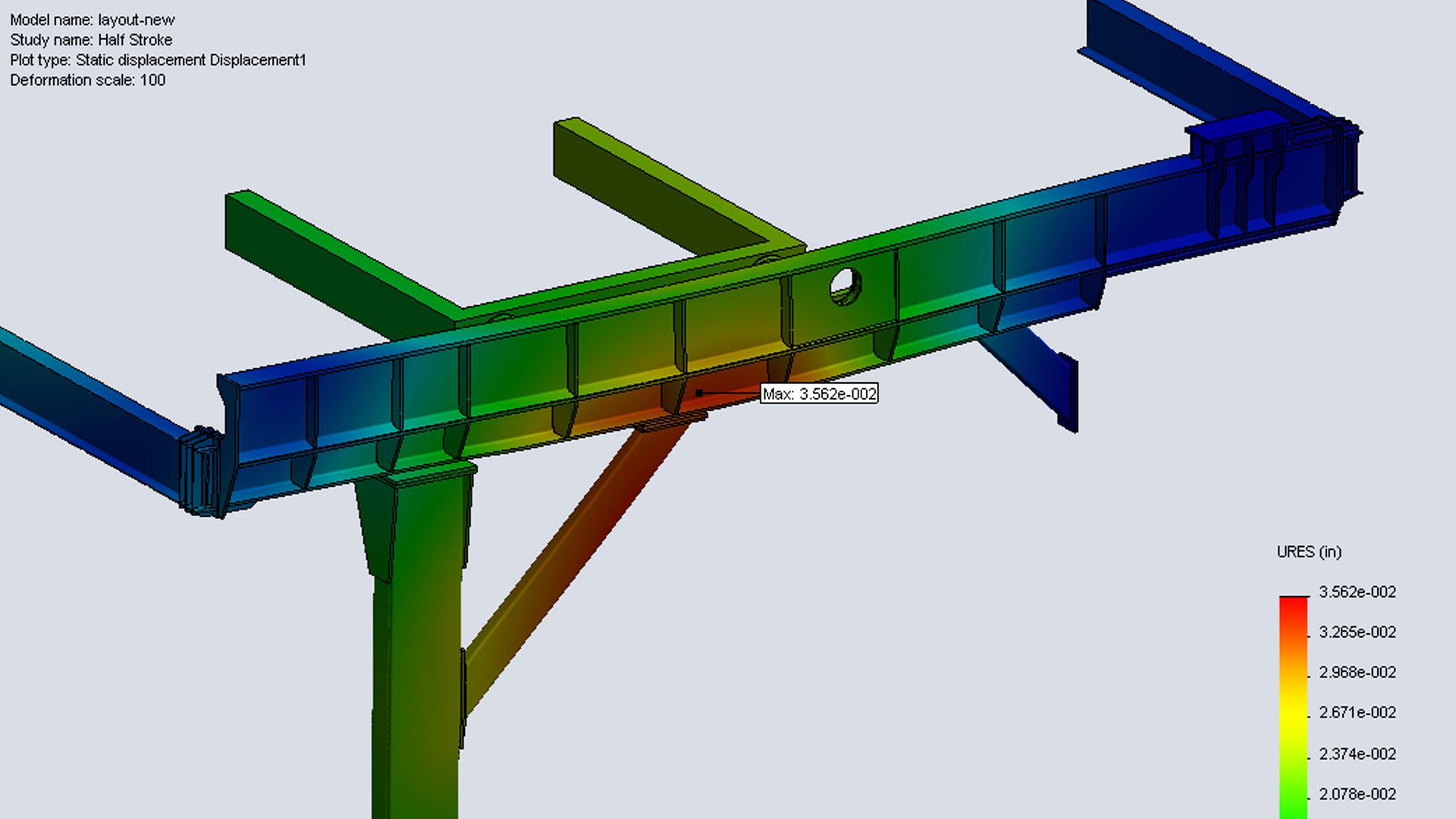

3. Precision Elevates Quality

Robots are engineered for accuracy. Their ability to perform tasks with exacting precision reduces variability and defects, leading to higher product quality and fewer customer returns. That level of consistency is nearly impossible to achieve with manual processes, especially in high-speed or high-precision applications.

Consistent quality not only strengthens brand reputation but also lowers the cost of quality control and warranty claims. When quality improves, so does customer satisfaction and your bottom line.

4. Minimizing Waste & Rework

Production errors don’t just impact quality—they cost time and materials. Reworking parts or scrapping components can impact profitability and disrupt schedules.

Robots reduce errors by minimizing variability in how a task is performed . Robots help maintain process discipline—whether it’s a pick-and-place operation, welding or a product inspection. That means fewer surprises on the line and a better use of your raw materials.

5. Flexibility In A Dynamic Market

A common misconception is that robots are only worth the investment in high-volume production. That might have been true 15 years ago, but not today.

Modern robotic systems are highly adaptable. With the right programming and tooling, a robot can be reconfigured for different parts, products or processes. Collaborative robots (in particular) offer added flexibility by safely working alongside human operators, making it easier to reassign tasks or adjust workflows without major reprogramming.

This makes them an ideal fit for high-mix, low-volume operations. The flexibility to adapt to product variations and seasonal demand, future-proofs your operations against market shifts. As your production needs evolve, your robots can evolve too—protecting your investment and supporting long-term scalability.

Calculate Your ROI Today

Curious about the potential ROI for your facility? Use the Robotics ROI Calculator from the Association for Advancing Automation. Enter your production data to estimate cost savings and payback period: https://www.automate.org/robotics-roi-calculator.

What’s Next?

Robotic automation isn’t about replacing people—it’s about using your resources more effectively. When implemented strategically, robots enhance the work your team already does, reduce operational costs and position your facility for the future.

At Seifert Engineering, we believe good automation starts with good engineering. We work closely with plant leaders to explore what’s possible, understand where the value is and design systems that make a meaningful impact.

Let’s Start A Conversation.

We’re here to help you think it through and help your facility be more productive. From initial concept and system design to programming, panel building and onsite commissioning—we offer complete Design & Build solutions tailored to your industry.

Reach out to our team to start a conversation about what robotics could look like in your facility today.