Why Autodesk Vault Is a Game-Changer for Complex Engineering Teams

If you’ve been in engineering long enough, you’ve seen this happen.

- A part gets machined from the wrong model.

- A drawing revision doesn’t make it to the shop.

- A “small change” turns into scrap, rework and a few uncomfortable conversations.

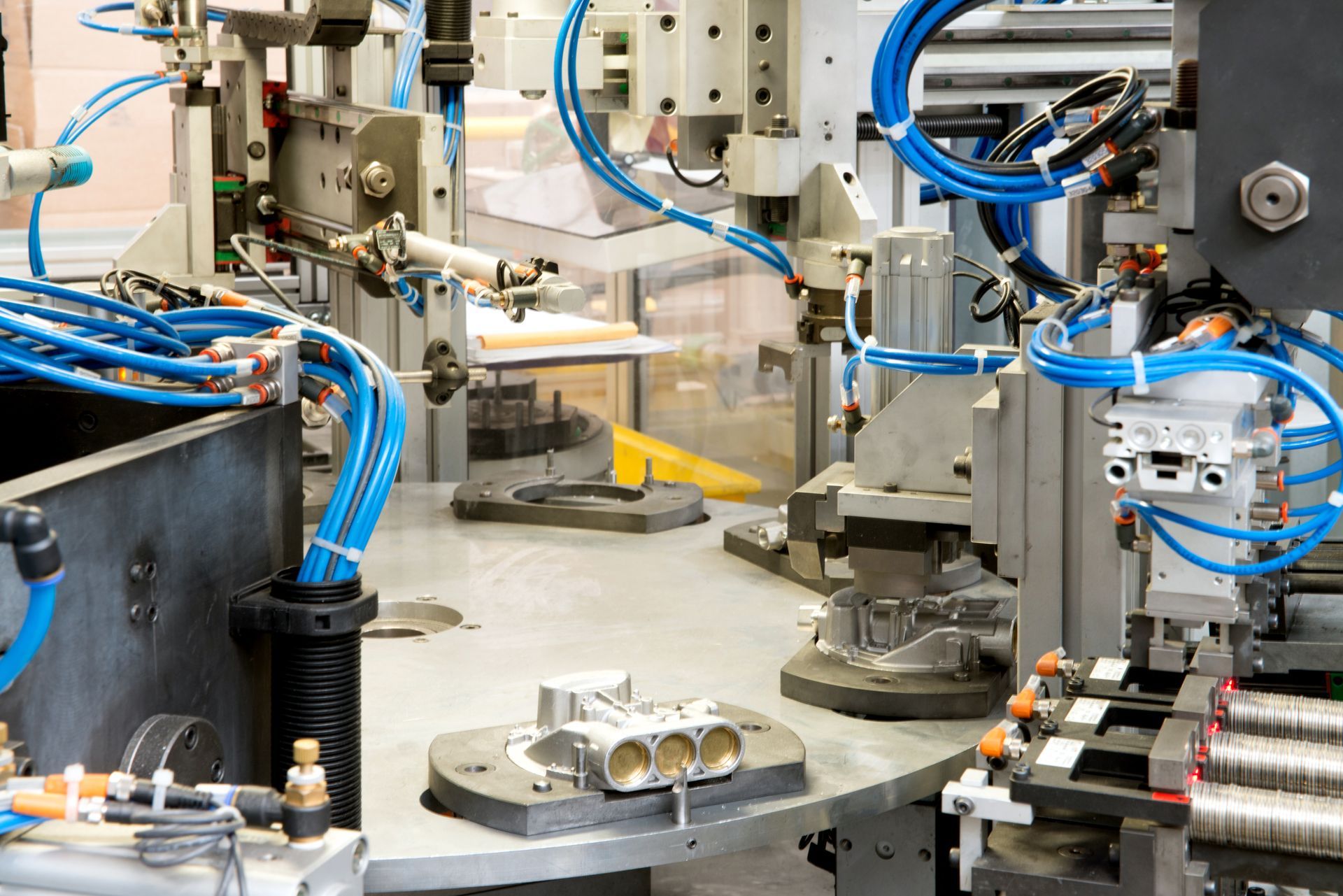

It’s rarely because someone wasn’t paying attention. It’s because the system allowed the wrong information to move forward. As projects grow, engineering problems stop being purely technical. They become version control problems. And once design intent starts slipping as files move from engineer to engineer—or from engineering to the shop floor—things unravel faster than most teams expect.

That’s where Autodesk Vault earns its place. Not as software. As control.

At Seifert Engineering, we don’t value tools because they’re impressive. We value them because they help keep engineering decisions intact all the way through fabrication.

Where Engineering Teams Usually Get Burned

Most teams don’t struggle because they lack skill. They struggle because information gets loose.

Shared folders. Local copies. File names that rely on memory and good habits. That approach works—until complexity increases. Then the margin for error disappears.

When the wrong file gets built, the impact isn’t theoretical:

- Material gets scrapped

- Machine time is wasted

- Weldments need rework

- Engineers are pulled back into cleanup instead of design

By the time an issue shows up, the cost is already locked in.

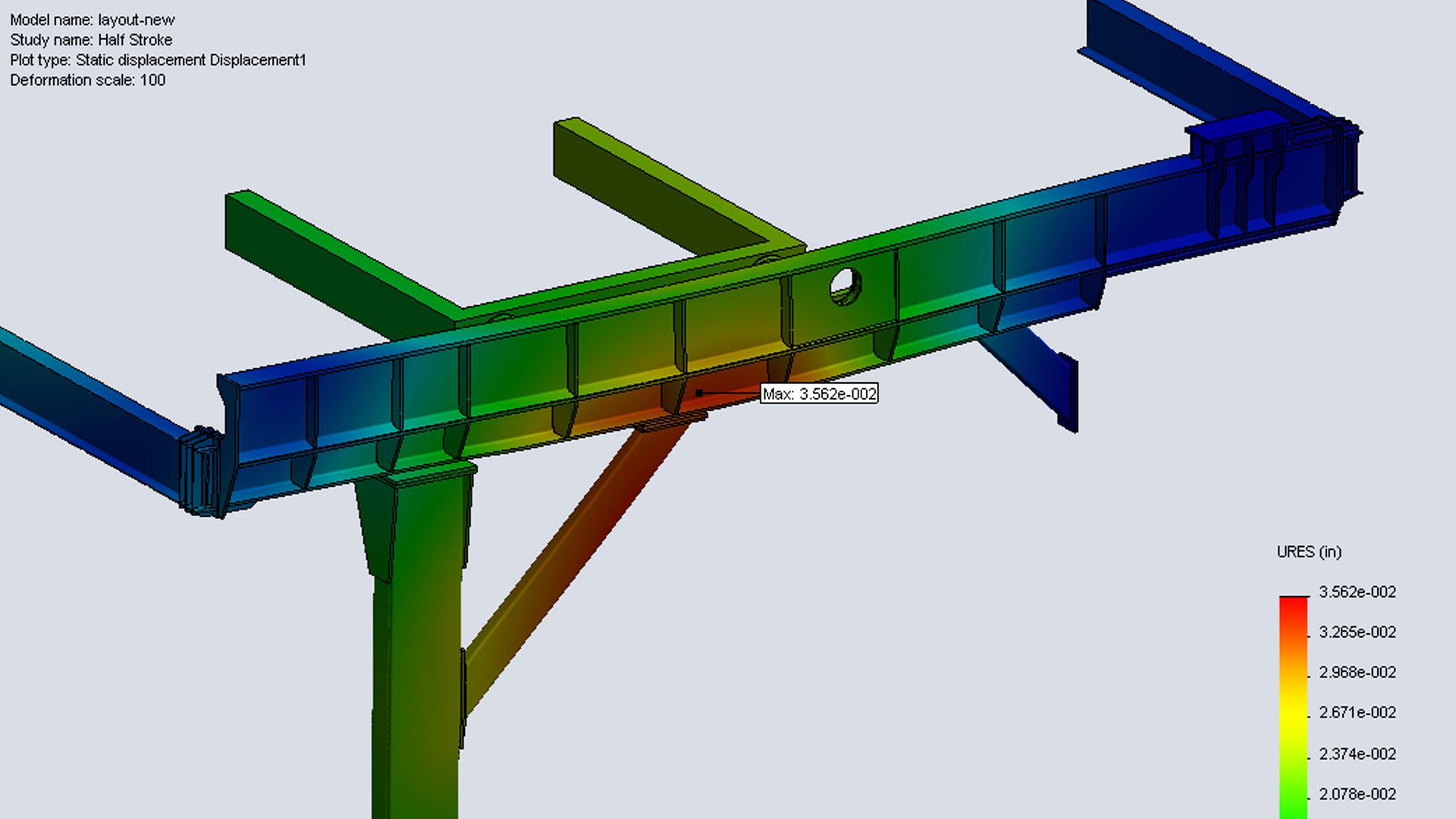

Autodesk Vault addresses a very specific problem: it creates a clear separation between work in progress and released design data. Engineers can iterate freely, while manufacturing sees only what’s approved and ready to build.

That clarity removes a surprising amount of friction.

Protecting Design Intent (Not Just Files)

Good engineering isn’t just geometry. It’s designing with intent. It explains why a rib exists. Why a tolerance is tight. And why one change was made instead of another. Without structure, that context fades. Someone opens a model months later and ends up re-solving decisions that were already made. Vault helps prevent that.

Versions and revisions are tracked automatically. Relationships between parts, assemblies and drawings stay intact. When something changes, it’s visible—and traceable. That matters when designs evolve. And they always do.

Change Management That Reflects Real Engineering

Engineering changes are unavoidable. What usually causes trouble isn’t the change—it’s how casually it spreads.

A quick note, a verbal update, a marked-up print… Everyone’s trying to help, but before long it’s unclear which version is actually in play as the final approved drawing.

Vault’s Engineering Change Order (ECO) workflows introduce a deliberate pause. Not red tape—a moment to check impact before a change moves forward.

Changes get reviewed. Manufacturing knows when a revision is final. Engineers don’t have to wonder whether something is “good enough to build” or still in flux. And speaking from experience, that discipline pays off quickly.

Less Noise, Better Engineering Work

As products scale, engineers spend more time managing files than they realize. Renaming. Revising. Double-checking that the right PDF is circulating. That background noise adds up.

Vault removes much of it. File numbering, revision tracking and release status happen consistently in the background. Engineers stay focused on fit, function, and manufacturability.

It doesn’t make engineers magically faster. It makes them less distracted. That’s usually what teams need.

The Tool Only Works If It Matches Reality

This part gets underestimated. Vault can absolutely create friction if it’s dropped in without understanding how engineering actually works. Rigid workflows. Folder structures that don’t reflect product architecture. Controls that slow iteration. We’ve seen that too.

That’s why we approach Vault as engineers first. We look at how designs move from concept to release, how changes really happen, and where teams tend to lose clarity downstream. Configured in the right way, Vault supports engineering judgment instead of getting in the way of it.

The Bottom Line

Autodesk Vault isn’t valuable because it manages files. It’s valuable because it reduces the chances that unclear or outdated information reaches fabrication.

For teams designing systems that will be built, installed and operated in the real world, that kind of control matters.

At Seifert Engineering, we use tools like Vault because we’ve learned—sometimes the hard way—what happens without structure. If you’re working to keep engineering decisions intact as complexity increases, we’re always open to sharing what’s worked for us. Just give us a call, and let us help you set up a Vault system that can enable you to be more productive.

FAQs About Autodesk Vault for Engineering Teams

What is Autodesk Vault?

Autodesk Vault is a product data management (PDM) system that helps engineering teams manage CAD files, revisions, and released design data.

Who benefits most from Autodesk Vault?

Teams working with multiple revisions, assemblies, or handoffs to manufacturing—especially as products grow more complex.

Does Vault slow engineers down?

When implemented well, it supports iteration while clearly separating in-progress work from released designs.

How does Vault help manufacturing?

It ensures manufacturing works from approved, current files—reducing confusion, rework, and downstream risk.

How does Seifert Engineering approach Vault differently?

We configure Vault around real engineering and fabrication workflows, focusing on manufacturability, clarity, and downstream impact—not just software features.