Enhancing Facility Upgrades With Point Cloud-Driven Design

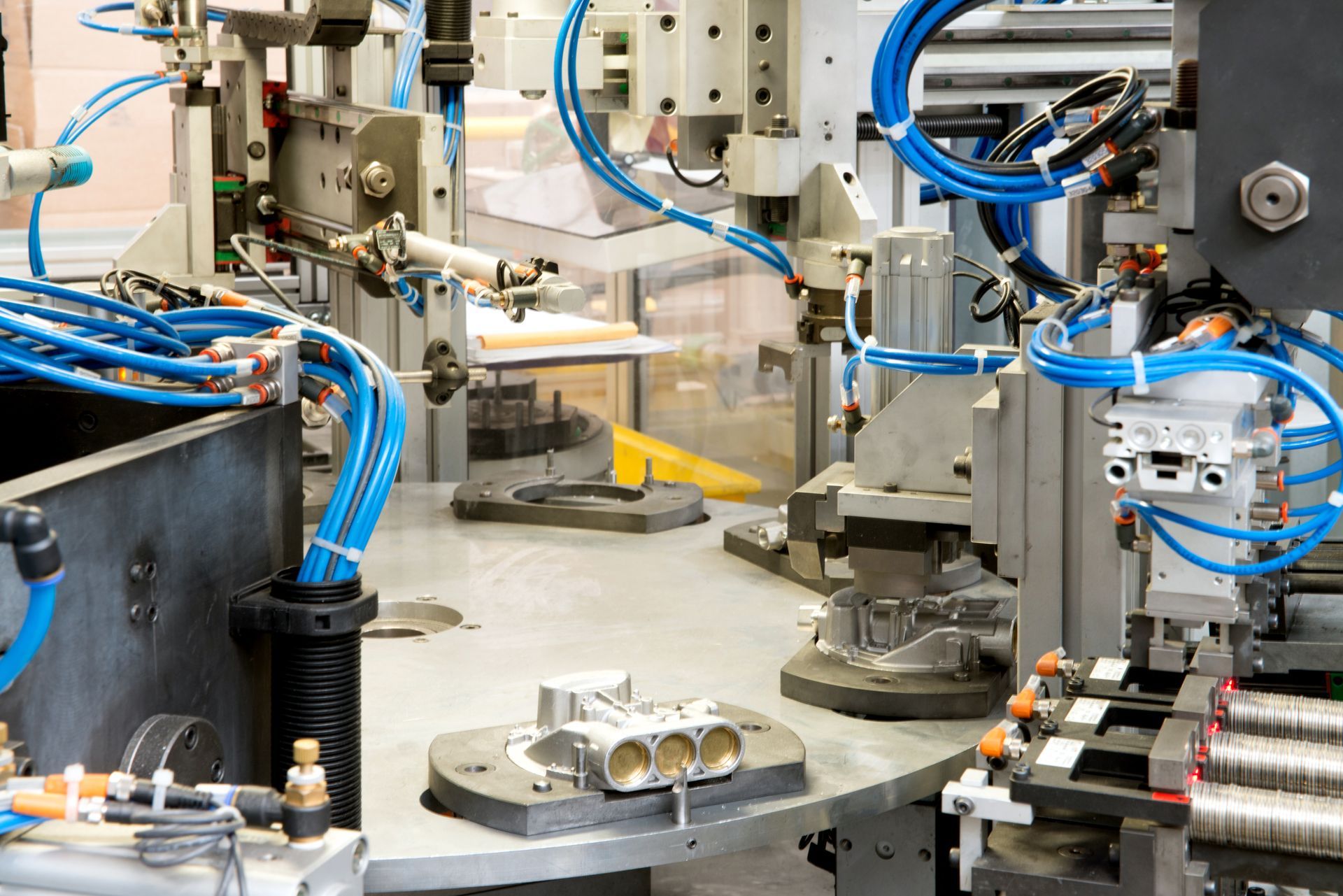

Upgrading or expanding an existing facility is one of the most complex challenges manufacturers face. Every project must fit seamlessly into a real-world environment that’s often full of legacy equipment, tight clearances and unknown obstacles. And when it comes time to expand or modernize a facility, gaps in documentation can make even a straightforward project feel like a maze. Even small inaccuracies in as-built drawings can create costly delays, rework or mismatched designs.

That’s why more manufacturers are turning to point cloud–driven design—a workflow that turns real-world spaces into precise digital environments. Point clouds give teams a clear, accurate picture of what they’re working with—no guesswork, no faded blueprints, no surprises tucked behind a support column.

At Seifert Engineering, we use point cloud data to help customers plan smarter expansions, design workflows with confidence, and move projects forward without the usual headaches that come with upgrading older spaces.

What Makes Point Clouds So Useful?

A point cloud starts with a 3D laser or LiDAR scan. The scanner fires out millions of measurement points, each one recording an exact X-Y-Z location. This creates a highly accurate digital representation of the facility as it exists at that moment—equipment, walls, mezzanines, conduit, pipe runs… everything.

For manufacturers, this precision directly translates into better outcomes. Teams can:

- Measure from the digital model instead of making repeated site visits

- Identify potential interferences before fabrication

- Plan equipment layouts more efficiently

- Build new designs that fit right the first time

It’s a way of turning a complex physical space into something engineers and decision makers can use to explore, measure and design within—all from the comfort of their desks.

From Scan to Smart, Usable Data

After a scan is collected, the raw data moves through specialized processing tools that help clean it up, aligning geometry and removing noise and irrelevant details. Multiple scan sets can be merged when a project covers large or segmented areas.

Once prepared, the point cloud is exported to a format that works easily with modern CAD environments. From there, it becomes the foundation for future designs—essentially a digital “as-built” model that informs every decision that follows.

This processing step is one of the biggest reasons point clouds are so powerful. Instead of trying to interpret messy or incomplete data, engineers work from a clean, reliable model that mirrors the real facility inch by inch.

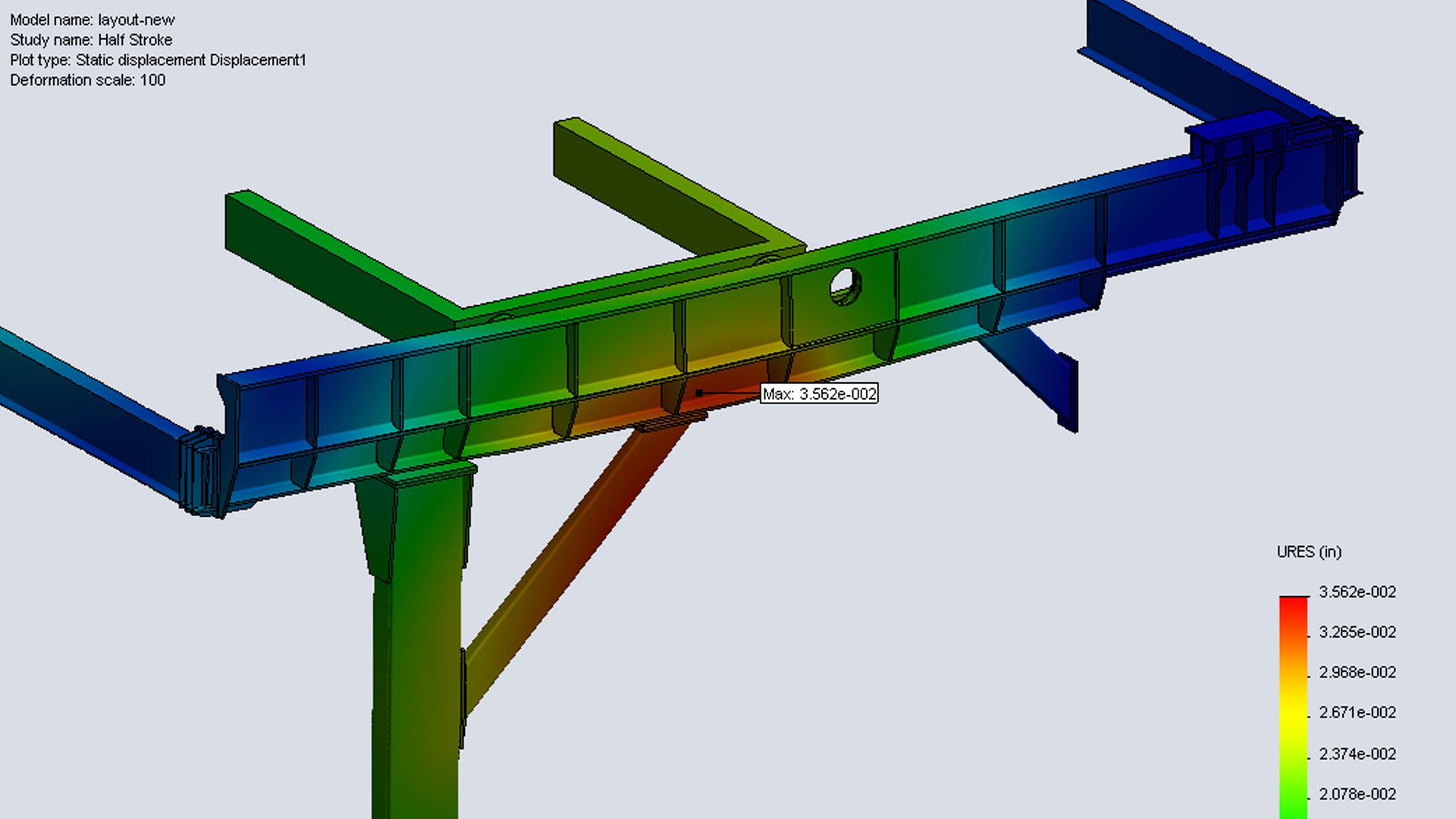

Designing Inside the Real Environment

The moment a point cloud is loaded into CAD, things get interesting. Instead of designing equipment or platforms in a blank workspace, engineers can build directly inside the scanned environment. It's the difference between designing a staircase using a generic wall height… and designing one that you know clears that pipe rack by exactly 2.37 inches.

Working this way makes projects move faster and reduces the friction that normally comes with upgrading older spaces. You can:

- Check clearances instantly

- Validate equipment fits before fabrication

- Build geometry that aligns with existing structures

- Catch conflicts while the design is still flexible

And because the model is visual and intuitive, approvals tend to move faster. Stakeholders can “see” the project long before installation day.

Better Planning, Better Workflow, Better Results

Whether you’re relocating a fabrication line, adding automation or expanding a production area, point cloud–driven design gives you the clarity needed to plan effectively. Teams can test different layouts, compare workflows and evaluate how new equipment changes material movement or operator access.

It also reduces two major project stressors: rework and downtime. When the model reflects reality, you’re far less likely to discover an unexpected beam, conduit run or floor variation during installation. That accuracy means fewer on-the-fly adjustments—and a much smoother upgrade process.

A Flexible Tool for Any CAD Workflow

Point cloud data integrates with most widely used design platforms, whether you're working in a mechanical, architectural or layout-focused environment. You don’t have to overhaul your entire workflow to use it; you can simply bring the point cloud in as a reference and design the way you always have—only now, you’re doing it with dramatically better information.

For many manufacturers, that’s a breakthrough: point clouds elevate the quality of the design work without adding friction to the process.

The Bottom Line

Point cloud–driven design gives manufacturers a more accurate, reliable, and efficient way to plan facility upgrades. With a precise digital snapshot of the environment, teams can make confident decisions, reduce installation risk and design solutions that truly fit the space.

At Seifert Engineering, we leverage point cloud data to help customers modernize with fewer surprises and better outcomes. Whether you’re preparing for an expansion, integrating new equipment or rethinking workflow efficiency, this approach creates a clearer path forward from day one.

FAQs About Point Cloud–Driven Design

What is a point cloud?

A point cloud is a collection of millions of measurement points captured by a 3D laser or LiDAR scanner, each one marking an exact X-Y-Z coordinate.

How accurate is point cloud data?

Very. It provides a high-fidelity representation of the real environment, making it ideal for tight clearances, complex layouts and equipment integrations.

Does point cloud data work with my CAD software?

In most cases, yes. Point clouds can be imported into many modern CAD platforms using native tools or common plug-ins.

Does this reduce site visits?

Substantially. With a complete digital model, engineers usually only need one initial scan visit—everything else can be measured virtually.

What types of projects benefit most?

Facility expansions, new equipment installations, layout optimization, automation upgrades and any project involving tight spaces or unclear documentation