The Future of Control: Why PLCs Are Critical to Smarter, Faster Manufacturing

PLCs are no longer just about control—they’re becoming your gateway to digital transformation.

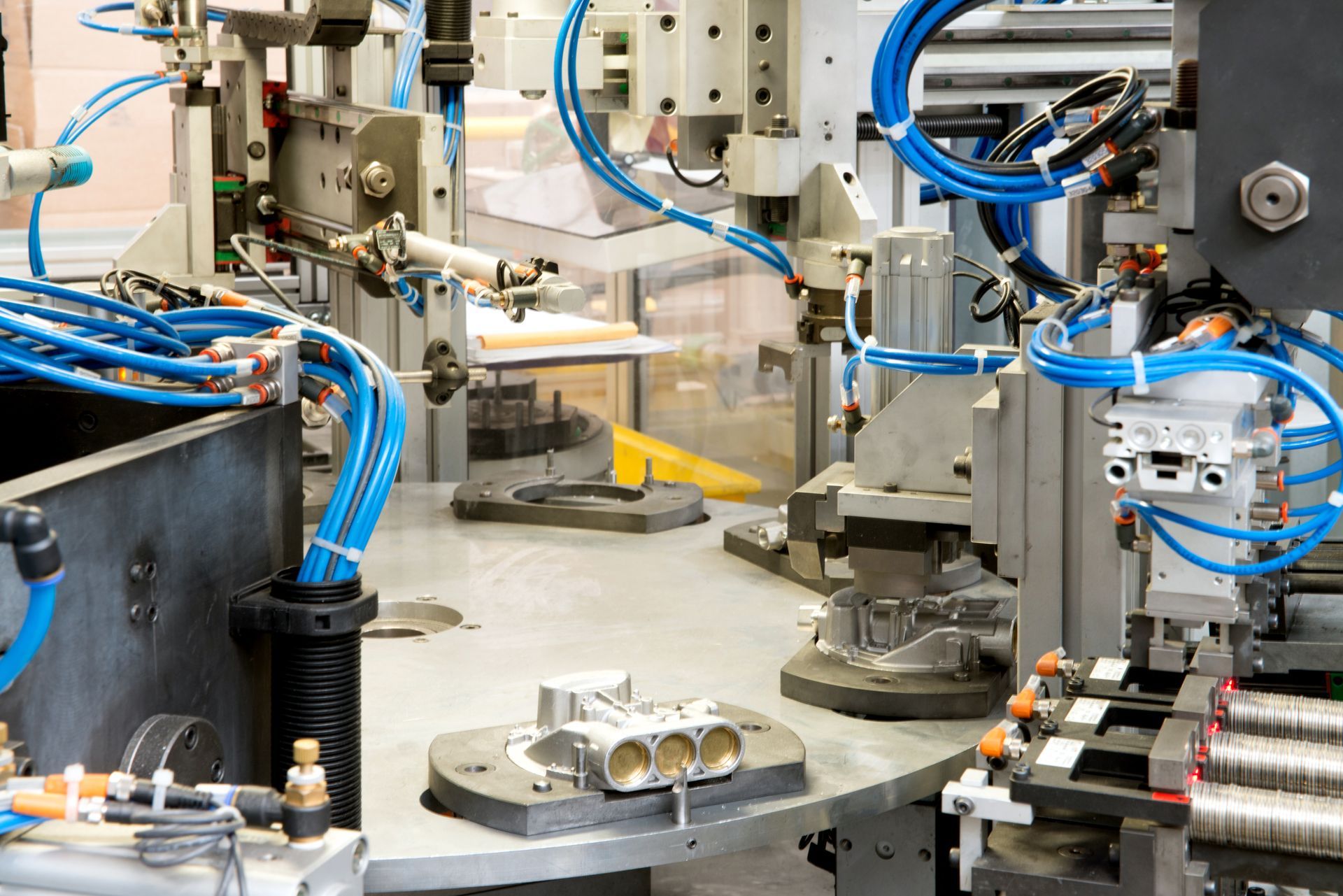

Programmable Logic Controllers (PLCs) aren’t just technical tools—they’re the silent workhorses powering the world’s most advanced production lines. Whether you're in automotive, food and beverage, or industrial manufacturing, PLCs sit at the intersection of uptime, throughput, and innovation.

Today, operations leaders are under pressure to do more with less—less downtime, less waste, and less labor. That’s where PLCs shine.

PLCs enable reliable, real-time control of complex machinery and systems. They’re the bedrock of modern automation, ensuring that processes run efficiently, errors are minimized, and systems are monitored continuously. But here’s the shift: PLCs are no longer just about control—they’re becoming your gateway to digital transformation.

Top 5 Thought Starters:

What should operations leaders be thinking about when it comes to PLCs?

1. Are your PLCs just running—or are they driving improvement?

Most existing systems can already gather data on temperature, speed, vibration, and runtime. But are you using that data for predictive maintenance or real-time decision-making?

2. How future-ready is your control infrastructure?

New PLC systems are built to integrate with cloud-based dashboards, mobile alerts, ERP systems, and more. If your current setup can’t connect, you’re losing agility.

3. Could smarter PLC programming improve yield or quality?

Advanced ladder logic can reduce cycle time, detect anomalies faster, and minimize scrap. The right engineering partner can unlock these performance boosts with the right programming logic.

4. Do your control systems talk to each other?

Interoperability between robotics, PLCs, sensors, and enterprise software is key to scaling smart factory initiatives. Siloed systems slow you down.

5. Are you planning for tomorrow’s workforce?

As skilled trades evolve, intuitive PLC systems with remote support, visualization tools, and diagnostics help your teams operate more efficiently—even with leaner crews.

What’s Next?

At Seifert Engineering, we work with plant leaders to rethink how their PLCs and control systems support the future of their operations. From initial concept and system design to programming, panel building, and onsite commissioning—we offer complete Design & Build automation solutions tailored to your industry.

Whether you're upgrading outdated PLCs, expanding production, or starting a smart automation initiative—we’re here to help you think it through.

Let’s start a conversation.

Reach out today to talk with one of our control systems engineers about what’s next for your facility.