Benefits of Machine Learning

In our previous blog we talked about AI, machine learning, and Keyence vision systems. We defined artificial intelligence and machine learning in manufacturing. That blog ended with how Keyence can help quality control through AI and Inspections. This is only the beginning, there are so many other benefits to machine learning we need to explore.

The Connection Between Machine Learning and Manufacturing

Machine learning is a branch of artificial intelligence. It's a process of feeding algorithms tons of data. This lets them learn and improve processes all on their own, without the help of humans. They're also not completely programmed by humans. In machine learning, data goes to the model and the model looks for patterns. Humans aren’t responsible for hardcoding these machines. Manufacturers use two types in production processes. These include supervised and unsupervised machine learning. Supervised leverages AI to draw patterns from large data sets with a predefined end. This is useful in determining the remaining useful life of a machine. It's also useful in determining the chances of specific equipment failure. Unsupervised identifies patterns from data sets whose outcome isn’t yet known. This type can detect unknown anomalies and faulty components in the production process. Machine learning is gaining popularity in manufacturing because of its benefits. Machine learning offers manufacturers many advantages.

The Manufacturing Advantage of Machine Learning

- Predictive Maintenance: Manufacturers spend too much time fixing breakdowns. They should be finding resources for planned maintenance instead. Machine learning can predict equipment failure with an accuracy of 92%. This helps them to plan maintenance with ease. This improves asset reliability and product quality.

- Quality Control: Machine learning computer vision algorithms use historical data. They do this to determine good and bad products. This automates the inspection and supervision process. These algorithms only need good samples in their training set. This makes a library of possible defects unnecessary. Created algorithms can also compare samples to the most common defects. This provides savings in visual quality control in manufacturing.

- Logistics and Inventory Management: Machine learning can automate logistics-related tasks. This boosts efficiencies and reduces costs. Businesses lose money every year from logistics and paperwork. Employees will spend countless hours on these tasks. These hours could be beneficial to have to work on and complete other important tasks. Automating these tasks can save time, which also saves money.

- Product Development: Making new products or improving existing products need data analysis. Machine learning can help collect and analyze product data. This will help you understand consumer demand, hidden flaws, and new business opportunities. This can help improve existing product designs as well as develop better products. Companies can reduce the risks associated with new product development. Machine learning allows them to make more informed decisions with better insights.

- Cybersecurity: Machine learning relies on networks, data, and technology platforms. It relies on both in person and cloud data. The security of these systems and data is critical. Machine learning can regulate access to valuable digital platforms and information. It can streamline how users access data, which applications they use, and how they connect to it. This helps companies protect digital assets by detecting anomalies and triggering corrective action.

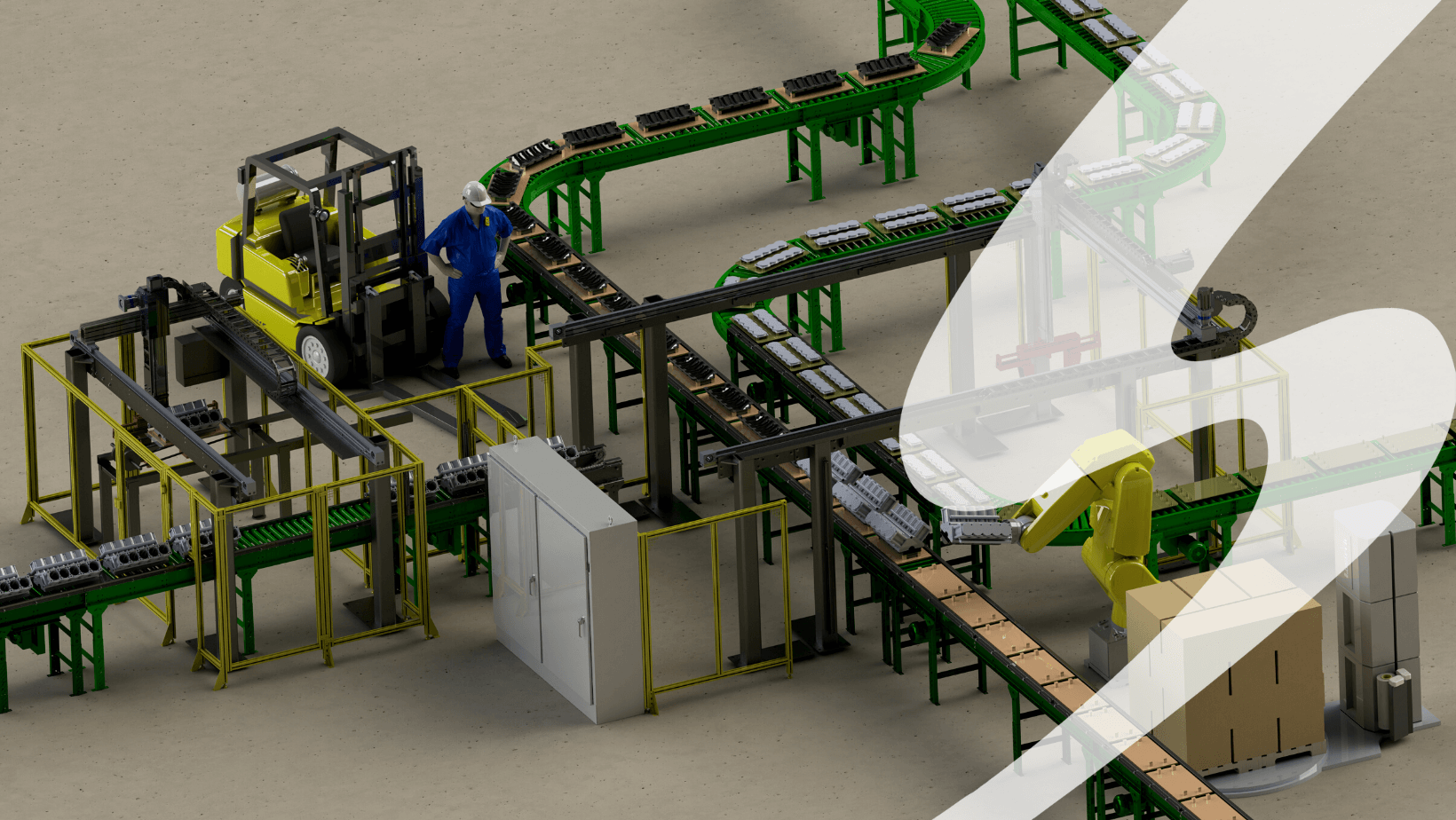

- Robotics: Modern manufacturing is still reliant on a human workforce. Automation in manufacturing is rising. Robots are now able to perform many complex tasks. Few areas need very high precision which only human specialists can provide. A major part of manufacturing could rely on robots in the future. These robots will be flexible enough to work together with humans. They will be able to operate in diverse and dynamic environments. They will also need minimal human supervision.

- Classification: These problems use an algorithm to assign test data into specific categories. Linear classifiers and support vector machines are types of classification algorithms. Decision trees and random forest are also common types.

- Regression: Using an algorithm to understand the relationship between dependent and independent variables. Regression models are helpful for predicting numerical values based on different data points. Some popular regression algorithms are linear regression, logistic regression, and polynomial regression.

How Can Seifert Help You Explore Machine Learning?

Ed Barth is a Certified Professional Engineer. He is also the Vice President of Engineering here at Seifert. Ed defines machine learning as “the capability of a machine to imitate intelligent human behavior.” He says Seifert "perceives “intelligent human behavior” as more than simple x-y movements we do with some gantry’s and such.” When asked, here’s what he had to say about Seifert and their connection to machine learning.

Q: How does Seifert determine if machine learning is right for a company? How do you recognize potential benefit opportunities from investing in machine learning?

A: “We could perform a Feasibility Study to determine if Machine Learning is a viable option for their certain application.”

Q: How important is machine learning to the future of manufacturing in America?

A: “Machine Learning is crucial due to the need for personnel to perform certain tasks in manufacturing. With the shortage of workers, implementing machine learning would most likely change that person’s task or duty rather than “cost them their job”.”

Q: Can you tell us about a previous project that Seifert Engineering worked on in this area?

A: “At Seifert, we have been involved with many projects that have relied on Machine Learning. Most recently, we were able to identify a manufacturing defect in a certain part that was traced back to a low-pressure hydraulic fault. Also, with today’s Cobots (Collaborative Robot), it’s very easy to train your system on the complicated motions required to perform a certain task.”

Conclusion

AI and machine learning is growing in the manufacturing industry with rapid speed. The process of machine learning utilizes your data to improve your operations. It makes collection and analysis of data simple. The benefits that come along with machine learning can be useful for your company and daily work. Your applications may be a great fit for implementing machine learning. Investing in machine learning processes can save you both time and money. If you're wondering if it's right for you, we're here to help. Here at Seifert, we have experience needed to tell you if machine learning is right for you. Contact us today to learn more.