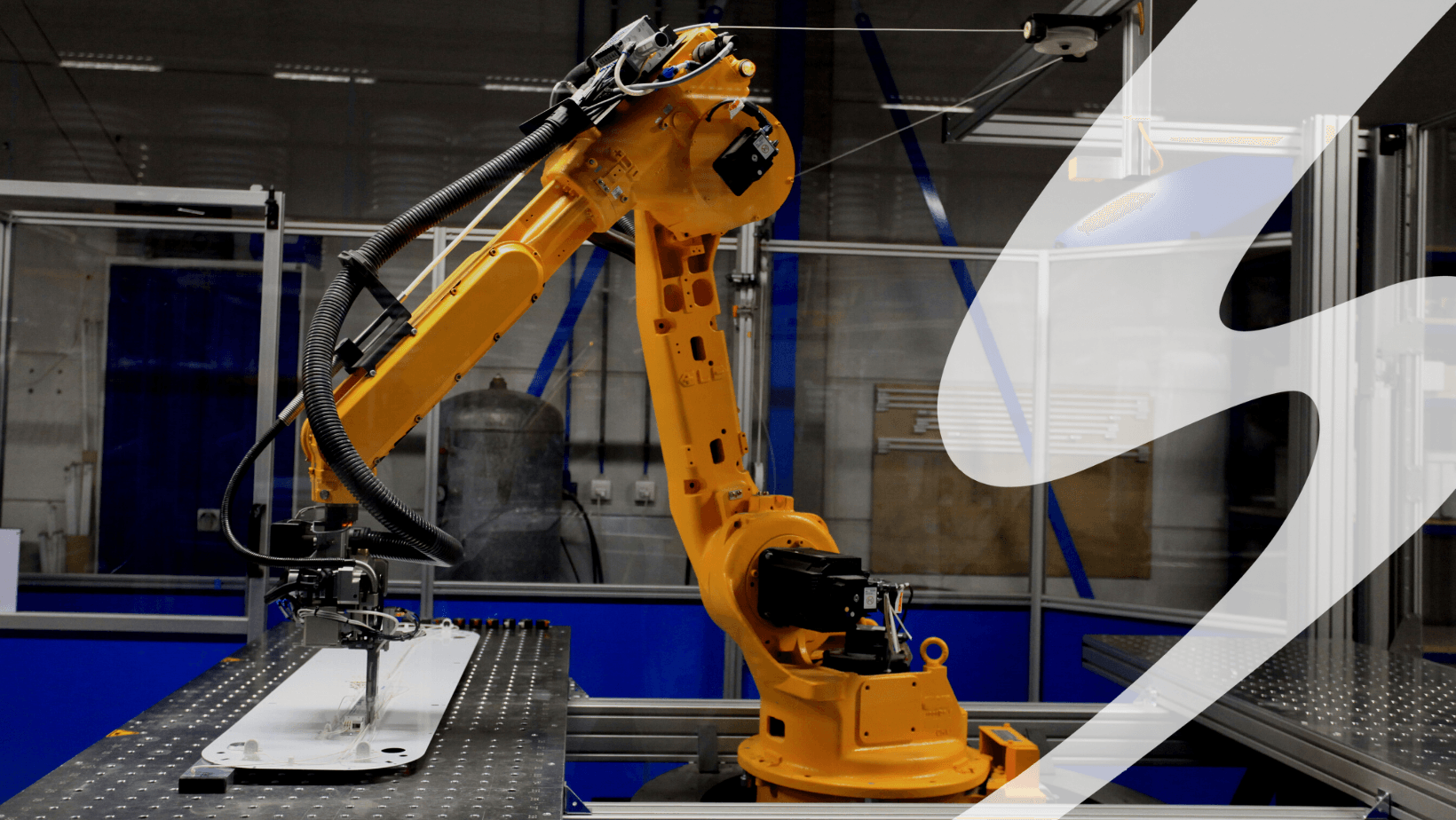

Robotics and Manufacturing

Robots in The Workplace

“Industrial robots are mechanical machines programmed to automatically perform production-related tasks in industrial environments.” These machines are beneficial in many different industries and applications. These robots come in a wide variety of models. The biggest company in the industrial robotics market is FANUC. They’re headquartered in Japan. Their robot machine selections vary. They have different reach distances and payload capacities. Robots also contain specific numbers of an axis of travel of their jointed arm. FANUC offers many different robot series, all serving different purposes.

These include:

- Collaborative robots

- Articulated robots

- Delta robots

- Palletizing robots

- Arc welding robots

- Top mount robots

- Paint robots

- SCARA robots

Of these, collaborative robots are the most buzzworthy. They're the latest technology to train and program robots with ease. They have enhanced safety features too.

What Do Industrial Robots Do? What Can They Do?

As already mentioned, different manufacturing robotics have different purposes in the workplace. Robots can perform assembly, pick/place, and testing/inspection. They could also perform dispensing and packaging processes. They can even perform painting and coating applications. What they are capable of depends on which model or models you choose. Manufacturing robots have fast-operating speeds and precision. They come with an accuracy that no human worker can match. This accuracy will reduce cycle times. Reducing cycle times reduces total production time, saving you time and money. These robots are here to enhance the careers of the current workforce. They are here to collaborate with workers, not replace them. Your employees will enjoy working with and managing these machines. Manufacturing robotics help to increase capacity and meet customers' demands. FANUC robots for manufacturing are easy to train and operate. They provide flexibility due to a range of application-specific options. They have straightforward integration and payloads of up to 2,300kg. They also have reached up to 4.7m.

Benefits of Using Robotics in Manufacturing

- Cost Savings- Companies begin using automation projects to save money. These minimize the time employees spend on dull and dirty tasks. Savings come from improved efficiencies and reduced risk of injuries. Manufacturers who invest in automation and robotics have higher efficiency rates. They also have better work environments.

- Improved Quality- Automated systems come programmed, meaning they usually don’t make mistakes. This eliminates potential human error too. Have your employees manage the robots instead of performing the manufacturing hands-on. This helps improve quality, consistency, and reliability.

- Enhanced Insights- Watching and recording jobs performed by the systems can be helpful. Process audits of the data collected from these robots push transformation. Companies with access to data are able to make improvements and reduce costs.

- Improved Employee Retention and Satisfaction- Train them to manage the robots. Those who oversee robotics instead of performing manufacturing tasks appear happier. This allows them to focus and work harder on other important tasks.

- Common Solutions- This allows manufacturers to use these solutions throughout the company. The same automation solutions can perform similar processes across the company. Common solutions make it easier to upskill the workforce. They also reduce spare parts and speed up deployment compared to customized systems.

- Center of Excellence- CoEs use data. They build common structures for all automation projects. This includes selecting the right automation partner. It also includes knowing the system design and how to put it in place it throughout the company. CoEs can also manage how to identify a new automation project. They ensure a quality structured process.

A Conversation with A FANUC Certified Operator

Richard Landals is our Sr. Project manager of Electrical Engineering here at Seifert. He is also a FANUC-certified operator. In a recent interview, Richard had some incredible insight into manufacturing robots. He gives us an inside perspective of how these robots are changing not only the world but also our company. Here's what he had to say:

Q: In your opinion, how are robots changing the manufacturing industry?

"Robots are able to perform repetitive motions, normally accomplished by multiple employees. With the use of Robots, we are able to increase production while reducing overhead expenses associated with today’s labor force. A robot can also operate 24 hours a day, seven days a week, without compromising quality."

Q: Seifert is currently setting up an R&D lab to enhance Robotics and IIOT integration. How will this process benefit the company once it's completed? What will you use the lab for? Do you believe it will improve operations?

"The R&D lab Robot will benefit both our internal engineers, as well as our customers, who have unique applications. We can setup and test their application and show them the benefits of using this technology. Once we have their confidence, we can develop our relationship and provide future opportunities to them. We are still developing the first application and specific operation is still in process.”

Q: What sparked your passion for manufacturing robotics? What pushed you to become FANUC certified? What's your favorite part about using this technology?

"I guess my passion for robotics started over 30 years when I became involved in Industrial Automation. For years, I’ve been applying the latest technology to our customer’s applications. Today. while using Robots for high-level operations, we can also capture productivity levels and push that data to IT services. In today’s environment, business is constantly evaluating their production throughput. My favorite part of using robotic technology has evolved over the years. Creating a specialized solution for our customers has always inspired me, providing a solution that few understand. As manufacturing challenges increased, I’m able to apply past success with future technology.

‘A problem is just an opportunity waiting for a solution.'"

Q: If You’re Considering Robotics for The First Time

If you're looking at implementing manufacturing robots, take a tactical approach. Take time to develop a strategy based on the advantages robotics can bring to your company. Look at the different robotic options for your company's needs. FANUC offers robotics brochures to showcase their different robots and their capabilities. Let us help you do these things and decide if robotics integration is the right choice for your company. Our team has knowledge in industries of automotive, tire and rubber, steel mill, pulp and paper, utilities, refining, plastics, and food processing. We will work together to upgrade processes and deliver improved products and efficiency. We strive to build a relationship and provide opportunities for your company.

Contact us today to learn more!